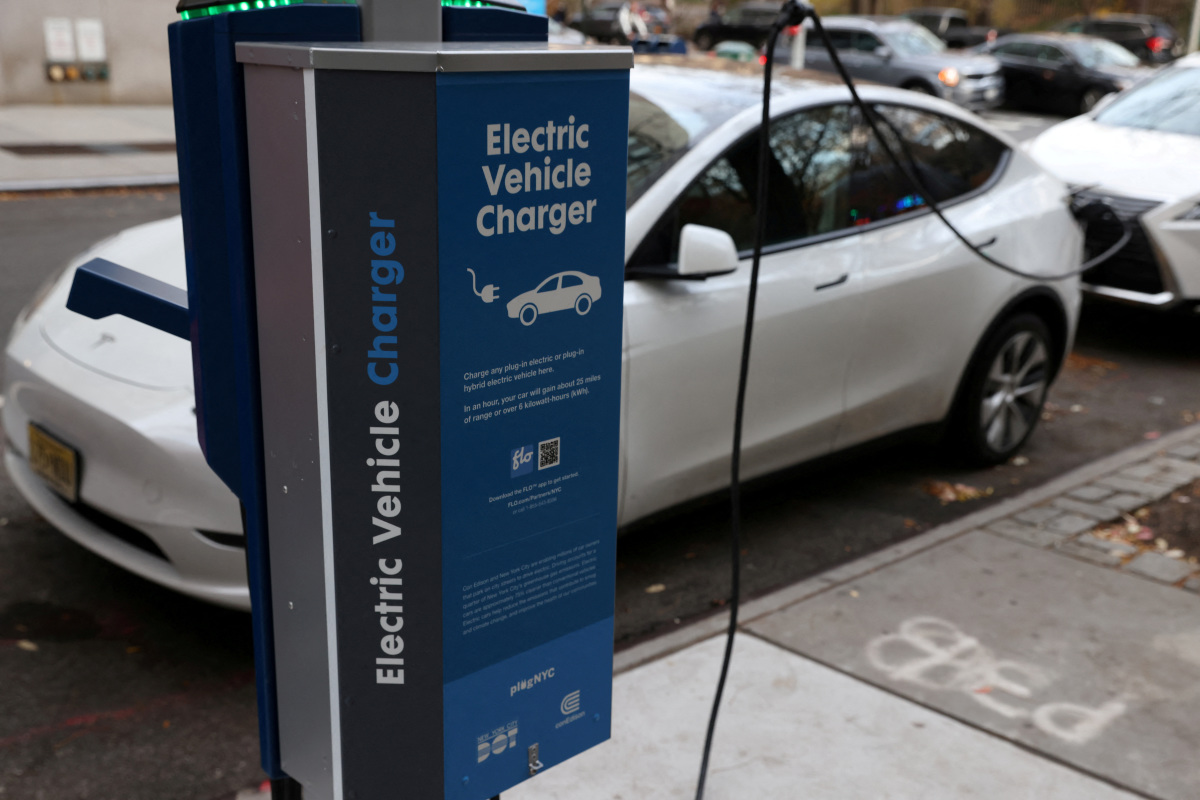

In 2021, cars and vans — both prime candidates for the electrification of mobility — contributed 8% of global direct CO2 emissions. To combat climate change, it is making more sense for more people to electrify light-duty transport (defined as vehicles less than 8,500 to 10,000 pounds). And this prospect becomes ever more appealing as the technology continues to improve and electricity’s advantage in driver experience, air quality and geopolitical security continues to rise.

To achieve that transportation transition, we’ll need minerals — and lots of them. And to provide those minerals, we’ll need to diversify and expand global critical mineral supply chains with all speed. Meeting this lofty goal will require clarity, commitment and continuous conversation across the economic and political spectra. Only with that collaboration can we achieve the supply lines needed to scale vehicle electrification at the pace needed to meet climate change goals without a mineral crunch.

Critical Mineral Supply Chain Expansion Is, Well, Critical

As we continue to execute the electric vehicle (EV) transition, it’s not enough to just build battery gigafactories. We also need to build out the mines and mineral processing facilities necessary to refine those minerals into the state usable in OEMs’ battery chemistry.

And with most existing critical mineral mining and processing capability currently residing in China, we need to focus on not just overall supply chain expansion but also supply chain diversification. Take graphite: With more than 90% of global graphite mineral processing and battery material production based in China, expedited expansion and diversification are essential to supply the security, stability and volume the energy transition will need in its graphite supply. And with the Inflation Reduction Act (IRA)’s battery material subsidies requiring North American or free-trade-agreement-member sourcing, demand for North American-processed critical minerals is projected to reach levels never seen before… and soon.

The problem? Building out those supply chains takes significant time, money, effort and expertise — and it’s difficult for mining companies and mid-stream processors to invest on such a scale before they have a buyer.

The Chicken-and-Egg Challenge of Critical Mineral Offtake Agreements

A similar sort of problem within carbon removal, transportation decarbonization’s next-door neighbor, has been addressed through advanced market commitments. However, no one is really discussing in appreciable depth the parallel phenomenon — or lack thereof — in the EV mineral space.

This quiet is for good reason. First, there is no industry precedent. Historically, original equipment manufacturers (OEMs) communicated their specifications for the equipment they needed to an established industrial marketplace, and potential suppliers proffered their product(s) once they had such material in hand. OEMs are reasonably reluctant to commit to purchasing a mine or plant’s outputs while the said plant is still applying for permits — particularly if the plant operator is new to the arena, but also (to some degree) regardless of how well-trodden the path to producing qualifying material from such a plant. Plus, OEMs don’t want to purchase EV battery material until they have a better sense of the coming years’ EV demand, nor do they want to count too much on IRA incentives when they fear the next election or debt ceiling negotiation could pull the rug out from under their driving-slippered feet.

However logical these concerns are, they pose a chicken-and-egg problem we must surmount in order to accelerate EV supply chain expansion and the electrification movement successfully. If OEM concerns are the chicken, then mineral processing investment is the egg: critical mineral processors will struggle to scale the facilities needed to supply domestically-produced EV battery material without forward commitments, firm or conditional, from OEM offtakers.

Why? Developing the facilities needed to process EV battery critical minerals in North America is incredibly expensive, even when an organization is simply replicating in North America a technology and process that they have already successfully honed somewhere else. Consequently, North American critical mineral miners and processors are ready and willing to invest the time, energy and resources into developing facilities on the continent, but they are somewhat hesitant to charge headlong until they can better gauge the scale and pace of demand.

The Collaboration Trifecta: Clarity, Commitment, Conversation

The good news is that a solution is readily achievable. After all, coming to North America makes good business sense, especially for experienced players. A diversified supply chain is a stronger supply chain. Plus, bringing production closer to the market reduces many of the risks and costs associated with long-distance transportation and geopolitical vagaries. That’s why, in early 2022, my company launched our Warren, Michigan, graphite processing plant, even before the U.S. announced its IRA incentives. As a burgeoning industry, together we can surmount the time, capital and predictability constraints posed by new infrastructure buildout — if we collaborate.

What does collaboration mean here? Mineral processors, OEMs and governments need to address three pillars: clarity, commitment and communication.

First, clarity: The IRA is a monumental step toward energy transition, but the industry needs further illumination on what qualifies — and a greater level of comfort that a future administration will not derail already-announced plans. The March 31 Treasury Guidance on critical mineral sourcing and processing was a great start, as it began to clarify how and where OEMs must source battery minerals and materials in order to qualify for incentives. And while no one can predict the political future, greater assurance that already-passed legislation will remain in effect for the announced duration would be key to accelerating critically needed EV battery mineral investment. The more clarification that OEMs receive, the more they can start to make concrete plans in good (financial and climate) conscience.

The second essential pillar is commitment. If the crystal ball is too cloudy for conventional offtake agreements, we can, similar to the world of carbon removal, innovate on our business plans just like we do on our technologies. Several OEMs are developing alternative routes, like financial assistance programs, to help mineral processors accelerate their North American expansion strategies. These programs are still in the early stages, but they’re a promising start and a clear indication of commitment. To build on this beginning, governments should add their support to these programs, either directly to mineral providers or through OEMs. (A benefit of the latter case is that OEMs understand the marketplace and can better evaluate which companies will receive the investment — governments provide the playing fields and the goalposts but do not pick who scores.) Either way, expanding such programs through a combination of OEM and government support would be a prime example of how collaboration can boost the commitment that mineral processors need to put shovels in the ground… and those shovels should be swinging now.

Third, and perhaps most important, comes conversation. Government, OEMs and mineral processors alike must engage in constant dialogue. Legislators are skilled at legislating; few of them are engineers, and more are business people than battery whizzes, but an understanding of the complexities involved in negotiating deals at this scale and speed is less pervasive within government than within boardrooms. By looking to industry as a guide, legislators can heighten the chance that they pass — and execute — laws that work in the real world with minimal friction and have a higher probability of achieving their intended objectives.

Collaboration: Key to Electrification’s Ignition

Constructing domestic EV supply chains poses a great hurdle but an even greater opportunity. To make the most of this potential, we need clarity, commitment and conversation. Together, OEMs, government and battery mineral processors can achieve our transportation decarbonization goals. We can build a diversified, stable, ample critical mineral supply chain — if we place collaboration at the forefront.

John DeMaio is the CEO of Graphex Technologies.

(Opinions expressed in this article are the author’s own.)

![Twitter starts paying hefty sums to creators via ads revenue sharing programme [details] Twitter starts paying hefty sums to creators via ads revenue sharing programme [details]](https://data1.ibtimes.co.in/en/full/787362/twitter-starts-paying-hefty-sums-creators-via-ads-revenue-sharing-programme.jpg)